Polyacrylamide

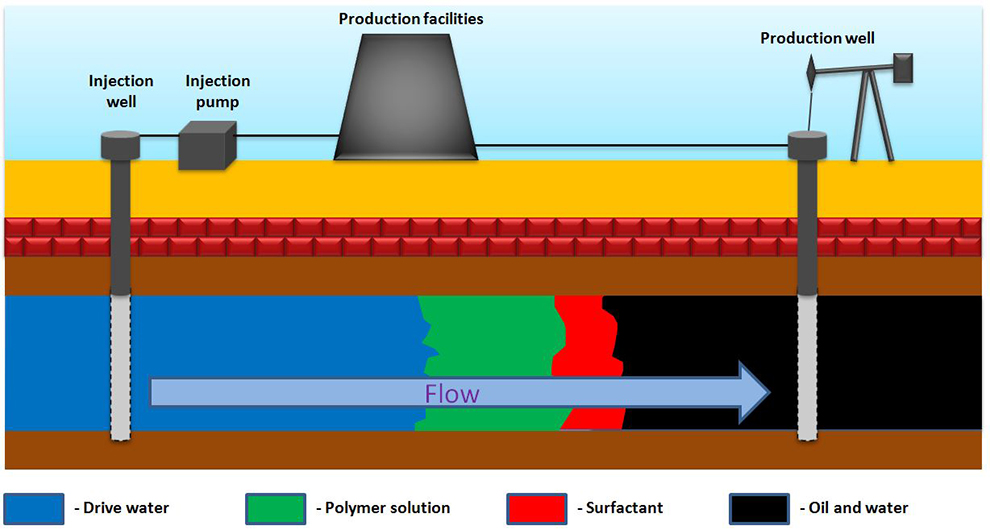

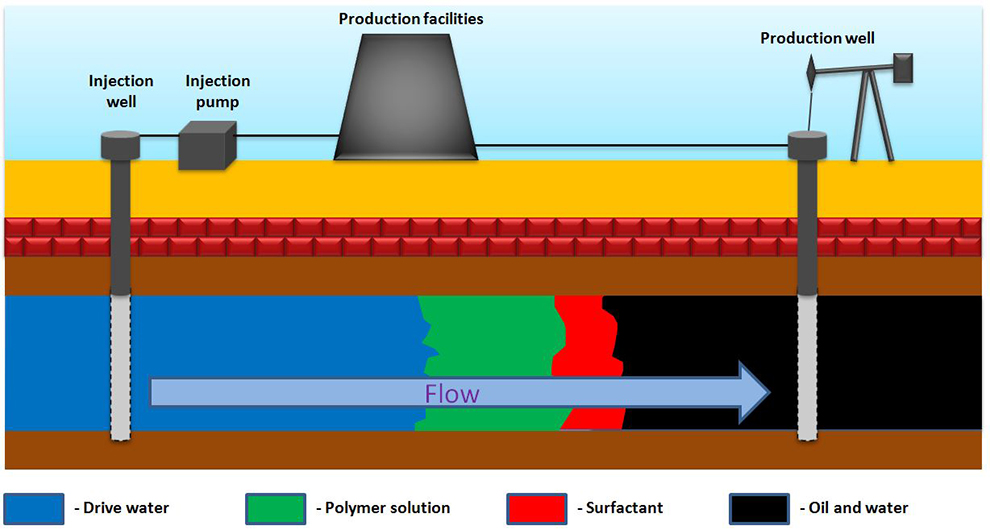

Polyacrylamide, a versatile polymer with a wide range of applications, has emerged as a key player in the realm of Enhanced Oil Recovery (EOR). In the quest to extract more hydrocarbons from reservoirs,

the use of polyacrylamide offers significant potential for improving oil recovery rates. Understanding the mechanisms by which polyacrylamide enhances oil recovery, exploring the different types available for EOR applications, and delving into the challenges and future prospects of this technology are essential for maximizing its efficacy in the oil and gas industry.

1. Introduction to Polyacrylamide in Enhanced Oil Recovery

Enhanced Oil Recovery (EOR) is like giving your morning coffee an extra shot of espresso for oil wells. It involves using various techniques to squeeze out every last drop of oil that primary and secondary recovery methods couldn't reach.

Polyacrylamide (PAM), plays a crucial role in EOR like the trusty sidekick to a superhero. It helps make the oil flow more smoothly, sticks to the rock like glue, and basically makes the whole process more efficient.

2. Mechanisms of Polyacrylamide in Improving Oil Recovery

Think of PAM as the oil recovery cheerleader, pumping up the crowd (or the oil in this case) by changing its viscosity. This helps the oil move through the nooks and crannies of the reservoir more effectively, leaving no oil behind.

PAM is like the smooth talker at a party – it bonds with the reservoir rock, creating a cozy environment for the oil to come out and play. This interaction helps release more oil and ensures that PAM doesn't just stand around looking pretty.

3. Types of Polyacrylamide Used in EOR Applications

Anionic,

Cationic, and

Nonionic Polyacrylamides . Just like different flavors of ice cream, there are different types of PAM to choose from. You've got your anionic, cationic, and nonionic PAM, each with its own special characteristics and uses in the EOR world.

Choosing the right type of PAM is crucial, like picking the right outfit for a job interview. Factors like the reservoir conditions, oil properties, and desired outcome all play a part in selecting the perfect PAM for the job.

4. Application Methods and Considerations for Polyacrylamide

Injecting PAM into oil wells requires a bit of finesse, like a delicate dance move. Monitoring techniques keep an eye on how well PAM is doing its job and whether any adjustments are needed to keep the oil flowing smoothly.

PAM may be the star of the show, but it also needs to play nice with other chemicals in the EOR cocktail. Compatibility is key to ensuring that all the ingredients work together harmoniously to achieve maximum oil recovery.

5. Case Studies and Success Stories of Polyacrylamide in EOR

Polyacrylamide has been making waves in the oil industry, with numerous success stories highlighting its efficacy in enhancing oil recovery. Field applications have shown significant improvements in oil production rates, with performance data backing up the claims. By increasing sweep efficiency and reducing water mobility, polyacrylamide has proven to be a game-changer in EOR strategies.

As with any technology, there are always lessons to be learned and best practices to follow when using polyacrylamide in EOR applications. Understanding the optimal injection rates, reservoir conditions, and polymer properties is crucial for success. By learning from past experiences and implementing best practices, operators can maximize the benefits of polyacrylamide for enhanced oil recovery.

6. Challenges and Future Directions in Polyacrylamide EOR Technologies

While polyacrylamide offers promising results in enhancing oil recovery, there are environmental and regulatory considerations that need to be addressed. Concerns about polymer retention, potential groundwater contamination, and long-term effects on the ecosystem require careful monitoring and mitigation strategies. Balancing the benefits of polyacrylamide with environmental stewardship is crucial for sustainable EOR practices.

Research and Innovation in Polyacrylamide EOR

To overcome current challenges and push the boundaries of EOR technologies, ongoing research and innovation in polyacrylamide applications are essential. Scientists and engineers are exploring new polymer blends, advanced injection techniques, and novel reservoir characterization methods to optimize polyacrylamide performance. By staying at the forefront of research and innovation, the future of polyacrylamide in EOR looks promising and full of potential for further advancements.In conclusion, polyacrylamide stands as a promising agent in the realm of Enhanced Oil Recovery, offering innovative solutions to boost oil production and maximize reservoir potential. As the industry continues to evolve, further research, advancements, and collaborations will be pivotal in harnessing the full capabilities of polyacrylamide for sustainable and efficient oil recovery operations. By staying abreast of emerging technologies and best practices, the integration of polyacrylamide in EOR strategies holds immense potential for enhancing oil extraction processes and meeting the evolving demands of the energy sector.